Waste heat from industry supersedes fossil fuels for DH generation in Sweden

2020-11-16

Waste heat (not to be mistaken for incineration of municipal solid waste) is any form of thermal energy produced as a by-product of industrial processes. Industries use various fuels to produce their products; while doing so, they often produce excess heat as a by-product in the form of steam, condensate or simply warm water. In many cases, this excess heat needs to be dissipated in order not to disturb the industry’s technological processes. Very often, excess heat is released to a nearby water reservoir or into the atmosphere via cooling towers. What does this mean from a thermal perspective? The heat is being wasted. It could instead become an important energy source for district heating.

In Sweden, waste heat alone provides more heat than is provided by coal, gas and peat combined.

With this, 9% of district heat is generated without adding any fuels to the system. This is good for the environment and wallets of DH customers.

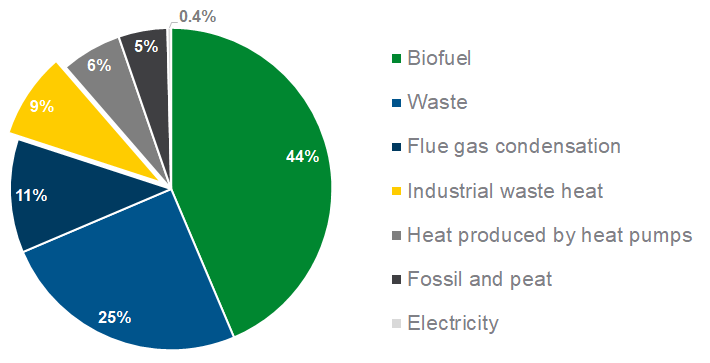

In Sweden, industrial waste heat sources provide 4.5 TWh. This is more than coal, natural gas and peat combined, which account for 2.6 TWh or 5% of the energy mix for district heating. For a country with a harsh northern climate, like Sweden, this is a substantial indicator as it means that 9% of district heating comes from a resource that does not require any added fuel. Sweden is one of the leading countries in the world when it comes to utilising recycled heat.

Figure 1: Energy sources for DH generation in Sweden in 2019. Total: 53.0 TWh

Source: Swedenergy (Energiföretagen), Sweco analysis

Today, industrial waste heat is used in district heating networks in about 80 locations in Sweden. Waste heat collaborations are relevant for cities of any size, like Oxelösund with 12 thousand inhabitants or Göteborg with a population of over half a million people. DH systems of any size can be designed to use any share of waste heat, irrespective of the network size. The range is from district heating networks, in which waste heat accounts for almost all district heating production, to district heating networks with less than one per cent waste heat in the district heating generation mix. There are large cities where industrial waste heat accounts for a large share. For example, Göteborg’s DH system uses the largest quantity of waste heat in Sweden, 1.1 TWh, which accounts for 30% of its DH generation mix.

Table 1: Examples of waste heat collaborations in Sweden

| Settlement | Population | Heat energy for DH (GWh/a) | Share of waste heat (%) | Origin of waste heat |

| Göteborg | 580 000 | 3 650 | 30% | Various, mainly oil refineries |

| Varberg | 65 000 | 190 | 70% | Pulp and paper industry |

| Luleå | 50 000 | 890 | 84% | Steel industry |

| Arvika | 26 000 | 135 | 6% | Foundry |

| Ludvika | 16 000 | 136 | 1% | Unspecified |

| Bromölla | 13 000 | 50 | 100% | Ceramic industry |

| Oxelösund | 12 000 | 100 | 98% | Steel industry |

Source: Swedenergy (Energiföretagen), Sweco analysis

Which industries can be sources of waste heat? The short answer is – more than anyone would guess! Waste heat can be sourced everywhere from large industries, such as paper mills, refineries and chemical industries, to small local industries, such as bakeries, foundries and printing houses. Even heat sources that operate at lower temperatures, for example data centres and shopping malls, can be used in district heating. These industries are common not only in Sweden but also in other countries. Using recycled energy in the form of waste heat is the whole idea behind district heating.

The substantial achievements with waste heat in Sweden are a result of successful collaborations between DH companies and industry. Typically, an industry sells its excess heat, and a DH company purchases this resource in order to generate DH to further retail it to customers. For industry, this collaboration means an additional line of income that can be an important factor in ensuring its industrial products are competitive. DH companies typically see this collaboration as a way of reducing costs for their business. Finally, the waste heat collaboration is an important factor for both industry and DH companies in achieving their environmental goals because utilising waste heat allows for the generation of district heating without adding any new fuels to the system. Knowing these advantages, waste heat collaborations are also well supported by local municipalities.

DH customers have a definite advantage if their heating companies use a waste heat resource. First of all, they get a cleaner environment. Second, people living in a neighbourhood with waste heat collaboration benefit from a more competitive industry that is likely to offer more jobs and contribute greater tax payments to the local community. Finally, waste heat collaboration can be the reason behind lower DH tariffs. A good example is Luleå, a Swedish town with 50 thousand inhabitants, located almost in the Arctic Circle. Luleå’s DH tariff is roughly half of the top-priced DH network in Sweden, despite its harsh climate and distant location. The explanation for this low DH price is a well-established collaboration between the Luleå DH company and the local steel industry SSAB, which provides 84% of the district heat for this network.

However, sometimes it turns out that a relevant industry is too far away from a district heating network. In this case, it may be too expensive to establish a collaboration. In some cases, an industry may also have difficulties guaranteeing waste heat supply at a level that is acceptable to a DH company, in which case there will be no cooperation.

There is a significant potential for waste heat utilisation in Ukraine, and it is not limited to sites with energy-intensive industries.

The SUDH team works on two projects aimed at waste heat utilisation, currently these projects are on a feasibility study stage.

The Sweden-Ukraine DH programme (SUDH) supports district heating in Ukraine to improve the technical standards and competitiveness of district heating while reducing its environmental impact. We can see that there are great potential opportunities for using industrial waste heat to supply Ukrainian district heating networks. There is significant potential for waste heat usage in Ukraine, and it is not limited only to sites with energy-intensive industries like steel manufacturing. Ukrainian industries need an extra source of income to increase the competitive advantage of their products, DH companies need cheaper and more sustainable sources of heat, and Ukrainian DH customers need cleaner and cheaper heat sources. We are therefore making a special effort to demonstrate the possibility of using industrial waste heat in SUDH projects.

Currently, SUDH team is working on two cases that can become examples of cooperation between private sector industries and municipal DH companies for the purpose of waste heat utilisation. This is an unprecedented collaboration in Ukraine.

Article prepared by: Ronny Nilsson, Julia Kosulko

Photo: Shutterstock