Mariupol city

Mariupol, near the Sea of Azov, is home to 450,000 inhabitants. It is one of the ten largest cities in Ukraine. Mariupol is also an important industrial city with operational metallurgical combinates.

Mariupol was selected for the SUDH programme based on the application from the city and its DH company. Read more here.

The Mariupol DH company and its long-term strategy

The Mariupol DH company (Mariupolteplomerezha) was established in 1967. The main task of the company was to ensure reliable provision of district heating (DH) and Domestic Hot Water Supply (DHW) services to its customers. Almost all the customers of the DH Company were households (99.4%); the share of budget institutions was 0.15% and other customers 0.45%, in terms of number of administrated customers. DHW was only provided during the heating season. About 100,000 (77%) customers use the DHW service.

Since 2007, Mariupol City Council has banned the disconnection of customers from DH as it sees DH as a strategic infrastructure that allows clean energy sources and high-quality heating services to be utilised.

The long-term strategy of the DH company in Mariupol was to transform the current production-driven DH system into a demand-driven customer-oriented DH system providing high-quality heating services with reduced environmental impact. To enable such a transformation, the DH company planned to interconnect small DH networks into larger DH systems. Ultimately, this would result in the creation of one or a few city-wide DH systems that allow for baseload DH supply from renewable and waste heat sources. These could be waste heat resources from a nearby industry, a Waste-to-Energy plant or a renewable energy source like sustainable biomass. The long-term strategy for DH in Mariupol also included restoring DHW service for year-round supply to all customers, as well as reducing disruptions of the heat supply due to malfunction or accidents at boiler houses or in the DH network.

The SUDH project

The initiated SUDH project would have covered the first steps of the Company’s long-term strategy by interconnecting three DH systems that currently operate individually, restoring DHW services and utilising an industrial waste heat resource for generating DH baseload.

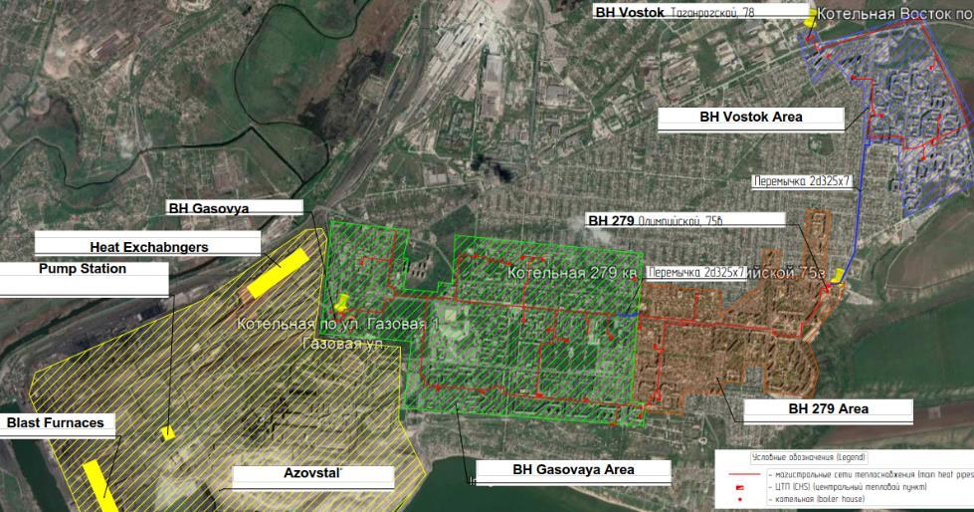

Three DH networks east of the Azovstal plant were proposed for interconnection – Vostok, Block 279 and Gasovaya, as shown in the figure below.

SUDH Project Components

Investment Component 1: Utilisation of waste heat from the Azovstal plant

The project proposed to use excess steam from the Azovstal plant as a resource to generate DH. This would also enable DHW provision to customers during non-heating periods.

The steel industry had facilities to generate steam from the exhaust gases of its production line. The steam was used partially for the Azovstal plant’s own needs, but there was a surplus of steam that was aired. The project proposed to use the steam surplus to generate DH and DHW.

This would have substituted natural gas, without adding any new fuel to the system, thereby leading to substantial CO2 emission reductions.

The available surplus of steam was expected to cover the DHW demand of the interconnected networks during periods of its availability.

Investment Component 2: Interconnection of three DH networks

In order to utilise the waste heat resource from Azovstal, it was necessary to connect three zones of DH areas, which were supplied by the boiler houses Gasovaya, Block 279 and Vostok.

The planned interconnected system would be supplied by heat generated from the waste heat resource as the baseload, supported by the Block 279 boiler house to cover peak loads. The Vostok boiler house would be closed

Investment Component 3: Installation of a flue gas condenser at BH Block 279

The Block 279 boiler house was undergoing an upgrade with the installation of two new gas boilers with flue gas condensers. It was proposed that a flue gas condenser (FGC) be installed for the remaining existing gas boiler as part of the SUDH project. The heat recovered by the FGC would be used to warm up the return water, thereby reducing the use of gas.

Investment Component 4: Improved Boiler House Operation

The interconnected system was expected to benefit from more advanced control and automation solutions. The main subcomponents included:

- Control system upgrade for the boilers and overall boiler house automation including SCADA

- New central control centre at BH Block 279

- New pumps with frequency converters at BH Gasovaya

Investment Component 5: Installation of IHS

The city has already started the installation of Individual Heat Substations (IHS) financed by an oblast programme. Thus far, 157 buildings out of total of 747 have had IHS installed. Continued IHS installation, as far as the SUDH project budget will allow, was proposed for inclusion in the project.

The two easternmost districts were prioritised, and full coverage for the Vostok area and 25% coverage for the Block 279 area were expected to be possible in the project budget. Priority was given to the Vostok area as it was considered beneficial for the strategy to take the Vostok boiler house out of operation. The exact number of IHSs to be included and the final selection of buildings for IHS installation had to be determined during the design phase.

The installation of IHS would also enable energy-efficiency measures for the connected buildings. IHS carefully calibrate heat supply to buildings to ensure they receive the right amount of heat at every given point in time as well as after thermal modernisation.

Table: Estimated savings per year

| Investment component | Gas savings, 1000 m3 | Electricity savings, MWh | O&M savings, kEUR | CO2 savings, tonnes |

| Waste heat | 5,389 | -231 | -8 | 10,295 |

| Interconnection | 1,098 | 674 | 59 | 2,674 |

| FGC | 111 | 216 | ||

| BH Operation | 801 | 43 | 16 | 1,593 |

| IHS | 958 | 196 | 12 | 2,020 |

| Total | 8,356 | 682 | 79 | 16,798 |

Positive impact

The proposed investment project would have contributed to improving the Mariupol environmental situation, primarily due to the reduction in carbon oxides and nitrogen dioxides. The installation of modern and efficient equipment would also lead to considerable savings in fuel and electricity, which would reduce the environmental impact.

Social benefits included improvement of the quality and reliability of DH and DHW services provided to the population. The proposed investment project would have brought benefits to about 30% of the 250,000 DH customers in Mariupol.

Financing of the project

The project would have been financed according to the conditions of the SUDH programme, namely:

- EUR 5 million loan from Nefco

- EUR 1.5 million grant from Sweden

- EUR 650,000 contribution from Mariupol

With the estimated yearly savings from implementing the project at 1.3 MEUR, the expected payback of the investment project was 5.5 years. It shall be noted that the component on utilisation of the waste heat resource had a payback below 2 years.

Current status

The feasibility study has been approved by the Board of Directors of Nefco as well as by the Mariupol DH Company and Mariupol City Council. In March 2021, Mariupol City Council approved the provision of a municipal guarantee to the DH Company to request loans for the SUDH project. Project implementation started in December 2021, but the project was discontinued due to the Russian invasion of Ukraine and the destruction of the project site.